Project Background:

Diesel engines often need to run for several hours, in the early stage of startup, the diesel engine temperature is low, the black smoke in the exhaust is more obvious, with the continuous operation of the unit, the temperature rises diesel fuel combustion is sufficient, the smoke generated will be greatly reduced. But then comes the gas with irritating odor, that is, nitrogen oxides, the higher the temperature, the less black smoke, nitrogen oxides, the more serious. The engine test stand mainly carries out testing experiments for internal combustion diesel engines, and the exhaust gas emitted from the laboratory mainly contains particles, nitrogen oxides and other air pollutants, so it needs to be treated in time to avoid causing greater pollution.

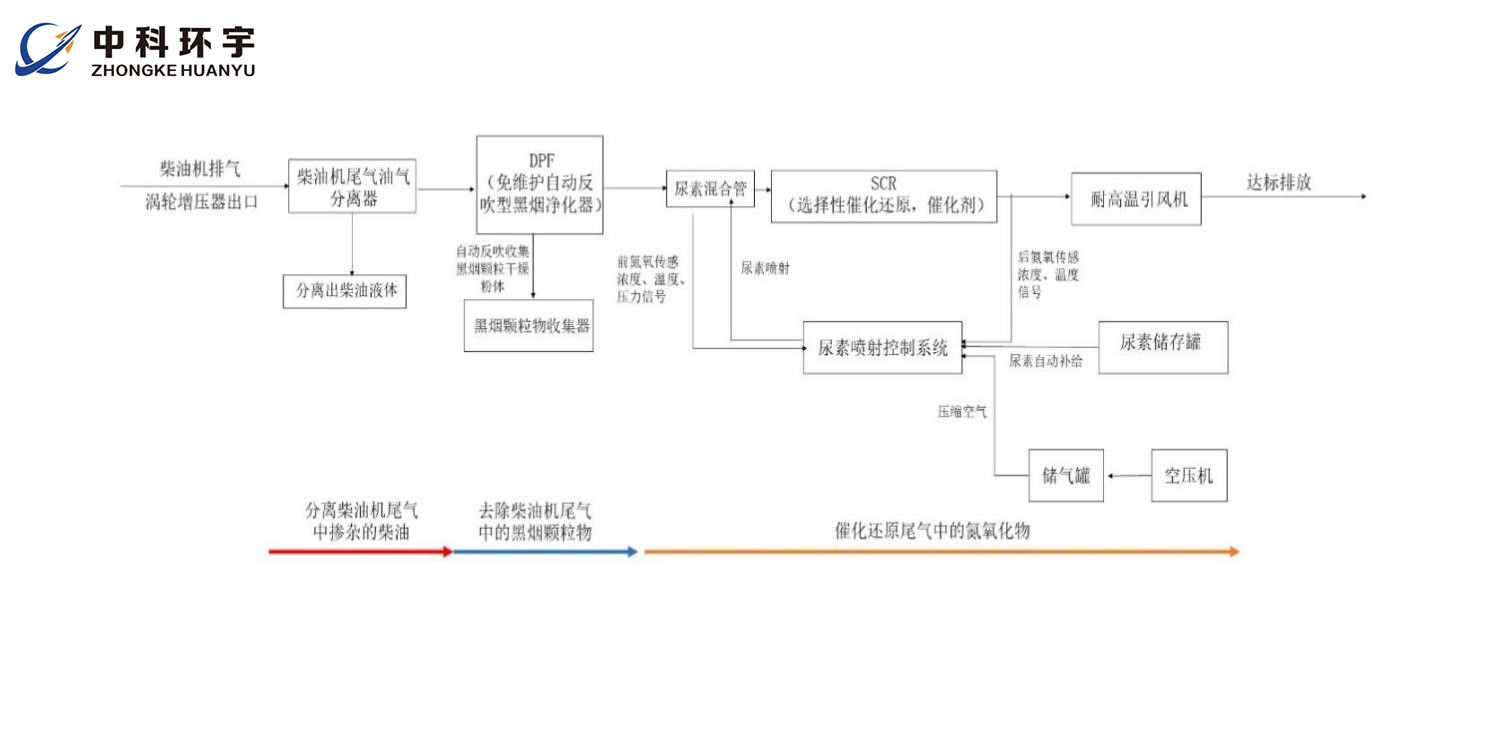

In response to the problem, we designed the treatment system mainly from 2 aspects: particulate management using particulate filters (DPF), physical filtration - maintenance-free black smoke purification device, NOx management using chemical reaction - selective catalytic reduction SCR denitrification technology route, after treatment of the exhaust gas to invisible black smoke, and at the same time on the harmful pollutants NOx reduction to harmless nitrogen, so that the treated exhaust gas Comply with the national standard "Comprehensive Emission Standards for Air Pollutants" GB16297-1996 pollutant limit indicators, reduce pollution of the environment.

TOP